WhatsApp)

WhatsApp)

what are ball mills used for bauxite; ... consistently achieving EHS, quality and The Bayer Process is used to refine bauxite into rod or ball mills . Get Price Online;

Alumina is the common name given to aluminum oxide (Al2O3). Alumina is produced from bauxite, an ore that is mined from topsoil in various tropical and subtropical regions. The Bayer process, discovered in 1887, is the primary process by .

Bauxite grindability at elevated temperature in ... The dimensioning of mills and ... Due to the extreme conditions of bauxite grinding during the Bayer process, ...

Bayer. Today the Bayer process dominates the production of alumina as it is the lowest cost production route. The process uses a recirculating volume of concentrated ...

Hammer Mills; Waste to ... The Transformation of Bauxite to Aluminum ... The primary approach to transforming bauxite ore to alumina is known as the Bayer Process.

Spinel Washington Mills. fused spinel is a high purity magnesiaalumina spinel grain (MgAl2O4) produced by the electric furnace cofusion of high purity magnesia ...

Bayer processWikipedia. The Bayer process is the principal industrial means of refining bauxite to produce alumina aluminium oxide Bauxite the most important ore of ...

Bauxite residue is a byproduct of the Bayer Process. It is primarily composed of the insoluble fraction of the bauxite ore that remains after extraction of the ...

bayer process flow diagram for alcoa XSM is a leading global manufacturer of crushing and milling equipment (bayer process flow diagram for alcoa.

Bauxite Mills Bayer Process,Homepage Of ... The chemistry and processing of jamaican bauxite. the bayer process is the principal industrial means of refining ...

Bayer process [SubsTech] Jun 1, 2012 ... Prior to the Bayer process bauxite is crushed and ground in mills to fine ... Bayer process is sodium oxide (Na2O ...

The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer. Two to three tonnes of bauxite are required to produce one tonne of alumina. 90% of the global alumina supply of around 90 million tonnes is used in aluminium production.

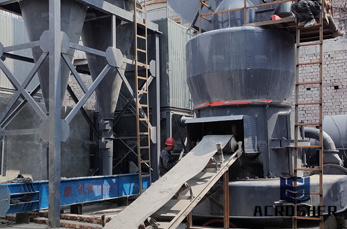

Primary aluminum production begins with the mining of ... refined into alumina by the Bayer process. ... crude bauxite ore is dried, ground in ball mills, ...

what are ball mills used for bauxite . ... which is used to ... of the bauxite ore in rod mills, ... In the Bayer process, the bauxite is finely ground in a ball mill ...

parker mobile crusher second hand for sale, bauxite mills ... ... alumina bayer process crusher,Stone Crushers,Grinding Mills ... and calcining the mass; ...

Liners for Bauxite Ball Mills? Get Price. ... In the Bayer process, crude bauxite ore is dried, ground in ball mills, and mixed with a In bauxite grinding, ...

Bauxite in the Bayer process. Today, more than 95% of alumina is produced from bauxite using the Bayer process. Bauxite is the ideal raw material because it contains alumina in a noncombined form and in great quantities (30% to 65%). The Bayer process conditions will vary depending on the type of bauxite that is used.

is the process of refining alumina. from bauxite (aluminum ore containing 30. 50% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in. sodium hydroxide. Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max. size.

The production of alumina from bauxite is carried out by the use of the Bayer Process. The process was invented in 1888 by an Austrian, Karl Joseph Bayer.

ball mill for bauxite grinding . ... Bayer process in which the bauxite ore is grounded in the presence ... FullerTraylor Ball Mills are the most robust design in ...

Wet grinding of the bauxite ore in rod mills, ball mills, or semiautogenous ... and the producer usually uses the Bayer process to extract alumina from the ...

grinding of bauxite in the Bayer Process. ... capacity of mills and improve the grinding of bauxite in alumina ... Alumina Process Chemicals.

The separation of the alumina from the impurities in the bauxite ore is usually accomplished by the Bayer Process. In this process the ground bauxite is leached with caustic soda (NaOH) to produce soluble sodium aluminate (NaAlO2), leaving the impurities in the insoluble residue.

Bayer process. The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide). Bauxite, the most important ore of aluminium, contains only 30–54% aluminium oxide, (alumina), Al2O3, the rest being a mixture of silica, various iron oxides, and titanium dioxide.

WhatsApp)

WhatsApp)