WhatsApp)

WhatsApp)

Grinding operation means grinding ball in ball mill grinding ... The Ball Mill Filling Ratio Automatic ... Selection of Grinding Ball and Ball Mill Lining ...

CRITERIA FOR MEDIA SELECTION Selection of grinding media depends upon several factors, some of which are interrelated. ... A typical ball mill has an L/D ratio of

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

Batch Grinding in Laboratory Ball Mills: Selection Function ... horizontal laboratory ball mill, ... Number of grinding balls 25 Pot/disc revolution ratio

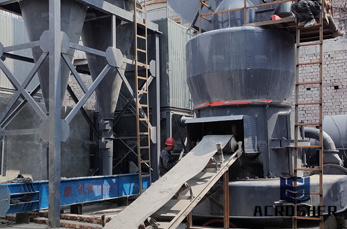

Ball Mills of for qualigied products and superior service, gives you the best Ball Mill,Superfine Ball Mill,Cement Mill,Cement Grinder, ...

grinding ball selection and ratio . grinding ball selection and ratio . Overview on the grinding mills and their dual pinion mill drives A lack of low strip ratio ...

In the present work, a grinding rate constant,, a selection function was measured for five solid materials using a tumbling ball mill, and effects of a grinding ...

Dry Ball Mill Introduction. ... Four Principles of Mill and Ball Ratio Previous page:Selection of Grinding Ball and Ball Mill Lining Plate. News.

Video embedded· Make a Ball Mill in 5 Minutes ... Many instructables refer to United Nuclear Ball Mills. ... And when your grinding or polishing is finished, ...

Grinding balls/sample/dispersant ratio ... Selection of grinding tools: ... Care must be taken when removing the grinding jar from the planetary ball mill as it

Batch Grinding in Laboratory Ball Mills: Selection ... Batch Grinding in Laboratory Ball ... the laboratory ball mill. value of the ratio of the ...

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ... number of grinding balls to charge ...

Inching Drive Backstops/Brake System for Ball Mills, Kiln Drives, and Incinerator Applications ... consists of replacing the grinding medium (steel balls) in the mill.

Grading production line of MQX series super fine ball mill ... selection and design ... the best effect of grinding. 3、Optimize aperture ratio and ...

The Selection and Design of Mill ... ball mill foundation design/wet grinding ball mill/ore dressing ... and the ball charge filling ratio of a ball mill.

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in . Where low contamination is important ...

Diagrind Bond Selection Guide Super abrasive Grinding ... grinding ratio. grinding ... Selective grinding of bauxite with ratio of Al2O3/SiO2(A/S) at ball mill ...

... influenced by the L/D ratio and the ball charge filling ratio of a ball mill. ... the ball mill in a Combigrinding plant ... Grinding ball size selection.

Past Auctions Biditup Industrial Auctions. global webcast auction big rock energy services late model pci industries mobile high pressure nitrogen generating unit ...

Gold ore ball mill is professionally ... Using it to process the gold ore can not only improves the use ratio of ... It uses unique grinding and powderselection ...

The specific selection function effect on clinker ... and the ratio of torque to. kVA. Figure 17 (right) ... ball mill wet grinding mill centerdischarge mill.

ball mill grinding ball selection and ratio Ball Milling ResearchGate. Best tungsten carbide balls in the steel grinding bowl or the step of ...

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time

WhatsApp)

WhatsApp)