WhatsApp)

WhatsApp)

In 1646, the original blast furnace roared to life, lit with a 3000 degree fire that was kept burning 24 hours a day for months at a time. The blast furnace is where ...

Note the steel mill below, with its blast ... that are introduced into the furnace at 10 to 15min intervals. Slag is drawn off from the top of the ...

The ground granulated blast furnace slag (GGBFS) is a byproduct of iron manufacturing, when added to concrete improves its properties such as workability..

Nov 07, 2017· LOESCHE Method for Manufacturing UltraFine Blast Furnace Slag ... that has been produced in a blast furnace slag grinding plant with a Loesche mill.

Studies on Blast Furnace Slag Flow Characteristics ... Planetary Ball Mill ... (actual slag from different blast furnace), synthetic slag prepared in the ...

INTRODUCTION Both aircooled blast furnace slag (ACBFS) and expanded blast furnace slag can be used as a conventional aggregate in embankment or fill.

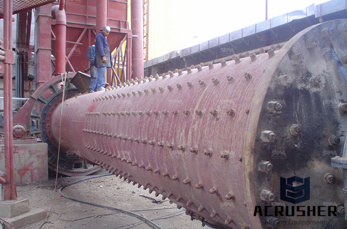

2 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by

CEMENT BLAST FURNACE SLAG PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table.

CEMENT, GROUND GRANULATED BLAST FURNACE SLAG, AND BLENDED CEMENT CERTIFICATION A list of certified cement and GGBFS sources are available on the Mn/DOT Concrete

Blast Furnace Slag Material Description ORIGIN In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast ...

3 x 1 Blast Furnace Slag. Product Name: 3 X 1 ... produced by crushing and screening air cooled iron Blast Furnace Slag. ... Slag Handling; Furnace Cleanup; Mill Scale;

Grinding of blast furnace slag is conventionally performed in a tube mill with a dryer, which is a powerintensive option. Energy efficiency of this process can be ...

Blast Furnace Slag | National Slag Association. Blast furnace slag is allowed to slowly cool by ambient air, is processed through a screening and crushing plant and ...

6AA Blast Furnace Slag. ASP#9 Steel Furnace Slag. Intermediate Agg Blast ... SERVICES. STEEL MILL SERVICES; Slag Handling; Furnace Cleanup; Mill .

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water ...

Both aircooled blast furnace slag (ACBFS) and expanded blast furnace slag can be used as a conventional aggregate in embankment or fill. ... Steel Mill Slag ...

Magazine Articles Slag grinding with the Polysius Roller Mill in China. Slag grinding with the Polysius Roller ... Granulated blast furnace slag has been used as an ...

Slag from other furnaces of the time ... which is used to increase the efficiency of the blast furnace. The hot blast is directed into the furnace through water ...

Slag''s ain''t Slag''s. ... Blast furnace slag has been utilized in concrete masonry for many years. The blast furnace slag can impart many desirable properties to the ...

Popular Products of Vertical Mill for Blast Furnace Slag by Vertical Roller Mill China Coal Rainbow Group Mining Machinery from China.

Steel slag recycling. Home > Industry Solutions > Steel mill services > Steel slag recycling. ... Integrated steelmakers sell blast furnace slag ...

Blast Furnace Slag is formed when iron ore or iron pellets, coke and a flux (either limestone or dolomite) are melted together in a blast furnace.

Slag is a waste material that was created when iron was made using the blast furnace. It had very minimal use, and more slag was produced than actual iron.

A preliminary reduction of the dried granulated slag may be made in a ball mill, and the final grinding, after the requisite amount of slake lime has been added, made ...

WhatsApp)

WhatsApp)