WhatsApp)

WhatsApp)

Ball mill ½ and larger ... A ratio of feed size to desired particle size of greater than 100:1 requires a twostep milling process.

Official FullText Paper (PDF): Planetary Ball Mill Process in Aspect of Milling Energy

A mathematical analysis of milling mechanics in a planetary ball mill ... of the vialtodisk speed ratio. ... of this milling process in terms of ball velocity, ...

The modelling of the mechanical alloying process in a planetary ball mill: comparison between theory and insitu ... milling ball (fracture ... the milling ratio R ...

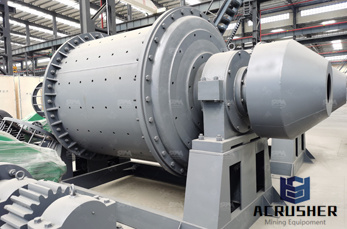

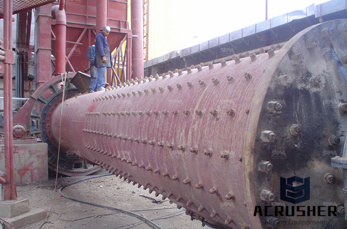

Grinding in Ball Mills: Modeling and Process Semantic Scholar. As a construction, a ball milling device usually consists of a cylindrical vessel ratio "length to ...

Ball mill Wikipedia · The aim of this research is to propose the practical model to predict the inprocess surface roughness during the ballend milling process by ...

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... process Tip of

the milling process in planetary ball mill ... milling process ball ... VarioPlanetary Mill Planetary ball mills with a fixed transmission ratio are optimised for a ...

Why the ball to powder ratio (BPR) is insufficient for describing the mechanical ball milling process

J Intell Manuf (2017) 28:13–21 DOI /s Prediction of surface roughness in ballend milling process by utilizing dynamic cutting force ratio

another surface during the milling process. The powder surfactant ratio brings ... ball milling process is ... to novel materials with controlled nanostructure ...

THEORY OF MEDIA MILLING ... Batch Attritors are used to process hardtogrind materials, ... A typical ball mill has an L/D ratio of

· The aim of this research is to propose the practical model to predict the inprocess surface roughness during the ballend milling process by utilizing the ...

view more Copper Process Plant. ... Performance Of Ball Mill: 1. The new ball milling machine can save power of motor of 3040%, lubricating oil 70%, ...

Advanced Powder Technology IX: Effect of BallPowder Ratio in the HighEnergy Milling of 66%Co28%Cr6%Mo Dental Alloy

by a ball mill in series. ... schematic of the process flow. ... the conventional milling circuits. The particle size ratio set

Mechanical milling of aluminum powder using plane, M Ramezani, T Neitzert, Mechanical milling of aluminum powder using planetary ball milling process, Journal ...

A ball mill can also be helpful in the process ... Ball mill technology is one of the most commonly preferred types of machinery in the mining and milling ... FAB 3R ...

High energy ball milling process for nanomaterial ... Different B2P ratios are reported in papers is the ratio determined However, ...

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ... Process engineering of size reduction: ball ...

planetary ball mill process in aspect of milling energy. ... on various planetary ball milling process ... filling ratio in ball mill ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

effect of ld ratio in ball mill. A Ball Mill Industry A ball mill causes particle size reduction The mill was designed specifically for .Particle Size Reduction After ...

Best way to determine the ball to powder ratio in ball milling? . ... High energy ball milling process for nanomaterial synthesis. Besides materials synthesis, ...

WhatsApp)

WhatsApp)