WhatsApp)

WhatsApp)

Limestone definition, a sedimentary rock consisting predominantly of calcium carbonate, varieties of which are formed from the skeletons of marine microorganisms and ...

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

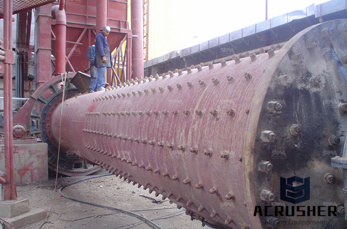

Final process of 5 th phase is the final grinding. There is a horizontal filled with steel balls. Clinker reach in this rotating drum after cooling.

Grinding definition, to wear, smooth, or sharpen by abrasion or friction; whet: to grind a lens. See more.

Clinker: compositional parameters. Chemical parameters based on the oxide composition are very useful in describing clinker characteristics. The following .

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by ...

The ingredients listed above include both naturally occurring materials such as limestone and clay, and industrial byproduct materials such as slag and fly ash.

Portland cement clinker overview. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 ...

The Largest Paving Contractors in Buffalo, NY. We do Asphalt Paving, Concrete, Drain Work, Seal Coating, Line Striping, Crack Filler Site Work. Contact Us!

Time Frames in Kansas Prehistory The time periods listed here are intended to be purely chronological in nature rather than units that ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

Clinker: compositional parameters. Chemical parameters based on the oxide composition are very useful in describing clinker characteristics. The following .

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 3 WORLD BANK GROUP • Storage of waste derived fuels in areas .

Antioxidant (Powder) 28 449 Apple Slices Diced 15 240 Aquafloc 10 160 Arsenic xide 41 657 Asbestos 22 352 Asbestos Fibre 20 320

Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process

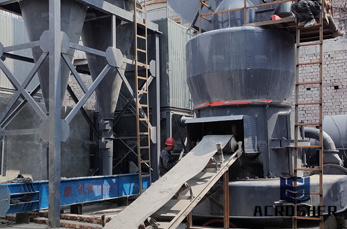

8 Polysius roller mills.....for raw material grinding. øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufac

Applications: nano grinding, size reduction, homogenizing, mechanical alloying, colloidal milling, high energy comminution: Field of application: agriculture, biology ...

Portland cement clinker overview. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 ...

Sep 04, 2013· re Cement Process Quality Control. 1. Mineralogy of Raw Material used for manufacturing of Cement. You need a good deal of reasonably pure limestone .

The History of Concrete: A Timeline. Cement has been around for at least 12 million years. When the earth itself was undergoing intense geologic changes natural ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

The Beginnings of Portland Cement. Portland cement is one of many materials that can be made by making a finelyground mixture of limestone and clay, and burning the ...

WhatsApp)

WhatsApp)