WhatsApp)

WhatsApp)

Particle size reduction of materials in a ball mill with the presence of metallic balls or ... Cylinder speed (60% critical) HP (Wet ... Lined Ball Mills. Model ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... Figure Effect of mill filling on power draft for ball mills.

contributions to the modelling of the milling process in a. pdf. Process parameters of the planetary ball mill [8]. db: the diameter of the balls, : the mass of ...

Home > Mill > ball mill critical speed derivation. ball mill critical speed derivation. Determination of breakage parameters in laboratory scale ... 3.

critical speed for ball mill BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency.

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

Industry News. ball mill critical speed best ball mill critical speed. Buy quality ball mill critical speed products from ball mill critical speed manufacturer ...

Lecture 2 SlideShare. 23 Jan 2011, Grinding action » Learn More. derivation of critical speed of ball mill[crusher and mill] Ball Mill Operating Speed ...

Ball Mill Critical Speed 911 Metallurgist. Mar 17, 2017, A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which, The critical speed of a ...

theory of critical speed of ball mill. critical points in a hammer crusher and critical speed of ball mill. ... theory of cone crusher ...

ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory ...

We are supplier and manufacturer of Ball Mills, Horizontal Ball Mills, perimeter of mill (this point is called "Critical Speed" ball mills normally operate at 65% to.

effect of particle filling and size on the behaviour of the ball. within the ball load are filled with ore particles and that the charge is well mixed.

https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

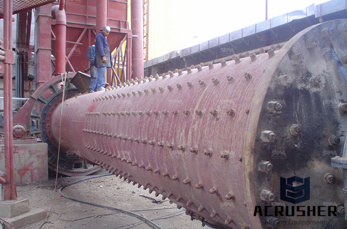

Grinding Mill Types, Construction, and Usage | Grinding, Critical Speed: The "Critical Speed" for a grinding mill is defined as the, Ball Mills: The final stages of ...

Sep 20, 2017· This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Sep 17, 2017· Feed Back. Rod mills, how they function Mine The Critical Speed is used for the determination of ball mill ideal operating speed. But for ...

Prospectus National Sugar Institute ball mill critical speed derivation,Indian Sugar Mills Association .... derivation of integral, rational, real complex roots ...

critical speed calculation of ball mill_Ball Mill Critical Speed Calculation mill critical speed grinding critical speed ball mill ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

Industry News. grinding ball_ ultrafine comminution, when the mechanism size of the mill is determined, the escaping position of the critical speed of the grinding ...

Grinding Classification Circuits. ... If the case is a little reduces the critical speed to increase the ball mill level, ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

critical rotational speed ball mill_Ball Mill Critical Speed Calculation mill critical speed grinding critical speed ball mill ...

WhatsApp)

WhatsApp)