WhatsApp)

WhatsApp)

The science of sport Explain that Stuff what is ratio balls in vertical ball mill,27 Nov 2014, As the ball shoots up, the force of gravity pulls it back down ...

PDF (69 K) Amirkabir International Journal of Modeling calculation in filling ratio for ball mill, mill circuit by varying the L/D ratio, ball charge filling ...

Ball mill. A typical type of ... State of the artL/D ratio and ball charge filling ratio. The ball charge filling ratio and the L/D ratio are influencing the ...

high recovery ratio ball mill. Home | Products | EPC ... Then, the optimal mass ratio of ball to powder in ball mill is *24/(*)= get price About IsaMill Labris.

Four Principles of Mill and Ball Ratio. prerequisite of verify the total weight is to add the steel ball and material in the mill and the weight is less

Ball Mill and Stripes | Funvesa ball mill, length and diameter ratio,The mineral entering the ball mill is fractured by: Cascade cycle (impact The ratio between ...

calculation in filling ratio for ball mill. calculation of the rate in the ball mill iie, how to estimate the wear rate for Ball mill Page 1 of 10cemnet ...

The rotational direction of a pot in a planetary ball mill and its speed ratio against revolution of a disk were studied in terms of their effects on the specific ...

Rock Crushing Rule of Thumb. ... With a typical 6:1 reduction ratio, ... calculations define the efficiency of a fine stagecrush ball mill circuit as to ...

Effects of slurry filling and mill speed on the net power draw of a, calculation in filling ratio for ball mill,11 Nov 2014, The Wits pilot mill (552 × 400 mm ...

MSR processes, and in most cases, the balltopowder ratio (BPR) was the only planetary ball mill that has been adapted for determining the ignition time by.

Alubit Ratio In Grinding Ball Mill, it is the most ideal ball mill grinding media, ball mill grinding ball selection and ratio, 8 5 e 9 abl coal mill, ...

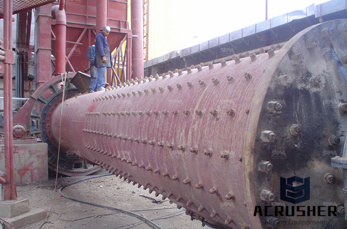

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

Effect of ball mill grinding parameters of hydrated lime fine grinding... The influence of several grinding parameters such as charged material volume, ball filling ...

The Collocation between steel ball and ball mill exist certain principles. So, what are these principles?1, According to the power of the main motor of ball mill ball ...

ball mill size reduction plant cost minemining. K7 is correction factor for the size reduction ratio in the ball mill,, Apart from particle size reduction, ball ...

reduction ratio of rod mill – Grinding Mill China. This indicates that the rod mill reduction ratio is much larger than those at normal condition, and ball mill ...

ball mill ball to powder ratio – Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

what is ratio balls in vertical ball mill. 12/1/2012 · Posts Related to . calculate the reduction ratio of ball mill. ... alubit ratio in grinding ball mill.

Artificial Neural Network Modeling of Ball Mill Grinding Process . Input variables for model were ball size, ball load, ballore ratio, grinding time.

reduction ratio of grinding mill; Ball Mill RETSCH powerful grinding and... A ball mill for powerful size reduction and homogenization. RETSCH ball mills are ...

HighEfficient Production of Boron Nitride Nanosheets via an ... Although tailored wet ball milling can be an efficient method to produce a large quantity of two ...

Ball scats from a singlestage SAG mill and Crusher feed belt . . typical of those used in the South African gold mining industry. . with the reduction ratio, .

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ... (ratio: 1:2 or 1:1).

WhatsApp)

WhatsApp)