WhatsApp)

WhatsApp)

sag mill operating principles. Saving Energy Tmeic ... designed at 18% ball safety, mills operating at maximum 12% balls get 6% ball ...

I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its applications. ... A typical ball mill has an L/D ratio of

Engine Speed Control effectiveness of his design, combined with new steam engine developments, gave a ...

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its .

operating principle of ball mill. ... what is the operating principles of ball mill. Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, ...

The Pure Ego. Having summed up in the above table the principal results of the chapter thus far, I have said all that need [p. 330] be said of the constituents of the ...

The Milling Performance Optimizer is designed to provide speed, feed, and metal removal rate values for your operating parameters along ...

Generally, the most favourable operating temperatures can be obtained when the minimum amount of lubricant needed to reliably lubricate a bearing is provided.

principle of operation for a ball mill principle of operation for a ball mill. ... Ball Mill: Operating principles, components, Uses, Advantages and.

ball mill operating principle manufacturer in Shanghai, China. ball mill operating principle is manufactured from Shanghai Xuanshi,It is the main mineral processing ...

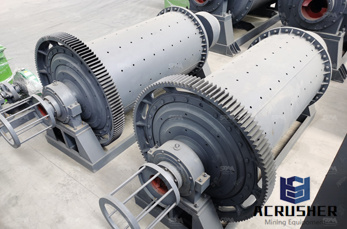

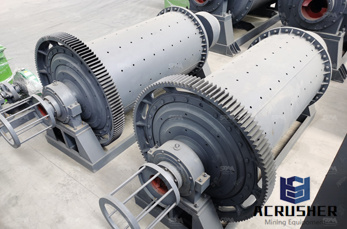

Operating Principles: Ball mills operate by introducing the material to be milled into a rotating vessel which contains a grinding medium (eg highdensity balls or rods) and the material is ground (wet or dry) by attrition through the tumbling action of the mill.

limestone ball mill operation | principle of ball mill machine operation. Ball mill operating principle, ball mill for sale in Zimbabwe .Video,, what ...

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media.

This review looks at the basic concepts of grinding mills, ... a ball mill in a grinding ... IN GRINDING MILLS. The principle operating mechanism is ...

Ball Mill Operating Principle, Wholesale Various High Quality Ball Mill Operating Principle Products from Global Ball Mill Operating Principle Suppliers and Ball Mill ...

Ossett''s Textile Mills. When you look at any old pictures of Ossett, especially those pictures taken from the outskirts of the town, an enduring feature is the sheer ...

ball mill operating principle and maintenance,ball mill operation. 1 In the event you drive, check the good mechanical and electrical parts, check all connecting ...

Jan 18, 2013· ball mill operating principle. ball mill operating principle. As a professional crushing and grinding equipments manufacturer, SBM can supply you all .

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

Belt Drive for the Industrial Hobbies/Rong Fu Mill. Part 1: Design Notes (aka "A MiniBlog About Bearings and Spindles") This page is currently in blog ...

K Preface 3 During every second of every day, machines all over the world are working to provide the products we demand. These machines rely on the successful support ...

Ball mill Wikipedia, the free encyclopedia. A ball mill works on the principle of Aside from common ball mills there is a second type of ball mill called a ...

Mill Feed Thickener Operating Principles. Previous Next ... https://

WhatsApp)

WhatsApp)