WhatsApp)

WhatsApp)

Ball Mill is the key equipment. The following is the factors that affect the efficency of the ball mill.

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

ball mill grinding efficiency YouTube. Feb 13, 2016, Contact Us For Help: wwastonecrushersolutionorg/solutions/solutions 2012 High Efficiency Cement Ball Mill ...

Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into ...

Combining hotcompressed water and ball milling pretreatments to improve the efficiency of the enzymatic hydrolysis of eucalyptus

Synthesis of Nanomaterials by High Energy Ball Milling ... It is a ball milling process where a ... the milling efficiency of the planetary ball was found to be ...

Functional Performance Analysis of Ball Milling. Excerpts ... It shows how grinding circuit efficiency is in reality comprised of ... Ball mill circuit ...

Mill (grinding) Wikipedia, the free encyclopedia. Ball mill . A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder ...

ball mill feed has been ... The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of ...

wat is average efficiency of a ball mill BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency.

IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY ... and efficiency of wet screening machines vs. length or area. ... followed by Secondary Ball Mill

for Accident Prevention Design for Energy Efficiency ... What is ball milling? A ball mill is a type of grinder used to grind materials

Read "The energy efficiency of ball milling in comminution, International Journal of Mineral Processing" on DeepDyve, the largest online rental service for scholarly ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into ...

Ball Mill Efficiency Factor – Grinding Mill China. ball mill efficiency factor. making your own porcelain ball mill jars With the PVC ones I would wonder if you ...

energy efficiency ball milling_Energy Efficiency and Saving in the Cement The potential opportunities for improving energy efficiency and lower CO 2 .

ball mill grinding efficiency ball mill efficiency. High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant.

Identification of Optimal Mill Operating Parameters. Apr 30, 2016 ... Abstract. It is known that ball milling is an energy intensive process and great efforts have ...

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed ...

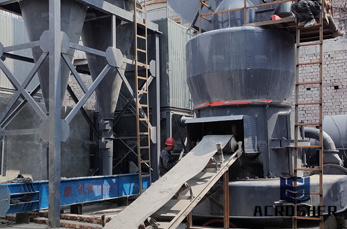

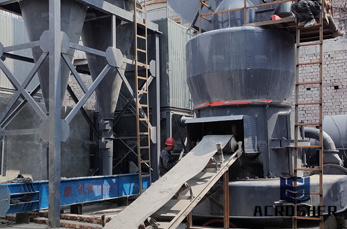

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building ...

ATTRITORS AND BALL MILLS HOW THEY WORK ... The harder the media the better the grinding efficiency and ... The critical speed of a ball mill is calculated as ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

Grinding Efficiency + Pdf. ... factors affecting grinding efficiency of the ball mills . Ball Mill grinding efficiency can be increased by making three changes in ...

WhatsApp)

WhatsApp)