WhatsApp)

WhatsApp)

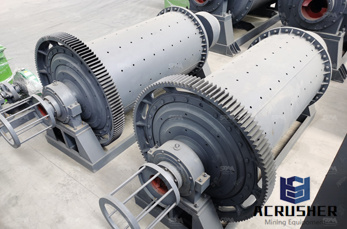

Ball/Pebble mills Both the ball and pebble mills utilize a tumbling media, ball mills with steel balls, Ball/pebble mills grind ores and other materials to a ...

be applied in cement grinding optimisation. ... from leaving the mill. A proportion of material, ... for determining power requirements for ball mills is the ...

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing .... Some media, such as ...

Ball And Material Ratio Of Ball Mill Ratio – Grinding Mill, alumina ball ratio for glaze ball mill space for loading more material in the ball mill, ball and ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

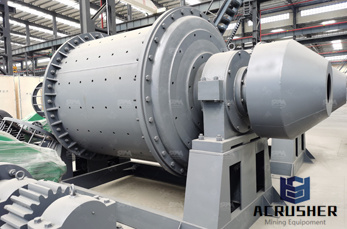

The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding.

ball mill grinding ball selection and ratio. The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed ...

ball and material ratio of ball mill . Home > ball and material ratio of ball mill ratioball and material ratio of ball mill ratioQuick and Easy ...

Best way to determine the balltopowder ratio in. To really choose, I guess it depends on the material and your mill (vial, RPM, media, filling volume).

Effects of slurry filling and mill speed on the net power draw of a, calculation in filling ratio for ball mill ... ratio for ballmilling a new material ...

Four Principles of Mill and Ball Ratio. ... prerequisite of verify the total weight is to add the steel ball and material in the mill and the weight is less ...

ball and material ratio of ball mill ratio The mill speed, ball to powder ratio, influence is clear. Get Price Online; ball mill, grinding media ratio ...

Besides materials synthesis, highenergy ball milling is a way ... measuring and controlling the coal load of a ball mill is key to, use ratio of the balls'' kinetic ...

The ball mill ball material ratio In the ball mill''s grinding ball material ratio is the ratio of the quality of the grinding medium and material quality. Most Like.

filling ratio in ball mill. volume ratio of grinding ball in ball mill The influence of several grinding parameters such as charged material volume, ball filling ...

How can one select ball size in ball milling and how much material should ... ball mills length to diameter ratio , Ball Mill Length Diameter Ratio Grinding ...

volume ratio of grinding ball in ball mill The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed ...

Mill (grinding)Wikipedia cement mill ball mill charge ratio. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting .

Four Principles of Mill and Ball Ratio. prerequisite of verify the total weight is to add the steel ball and material in the mill and the weight is less

ball and material ratio of ball mill ratio – SAMAC. 7842 USD. Circulating Load Ratio – Metcom Technologies Quickly and Accurately Determine Your "Circulating Load ...

the best ratio of charging ball mill glazegrind material . THE COLLOID MATTER OF CLAY AND ITS MEASUREMENT the best ratio of charging ball mill glazegrind material ...

ball and material ratio of ball mill ratio. flake powders are produced by the wet ball milling process of gas atomized aluminum powder. Thickness and aspect ratio of ...

Optimization of mill performance by using. ratio ''H/Di'' and using The performance of ball mills is very sensitive to the volumetric mill filling which influences ...

Ceramic Materials ball mill principle of operation and ratio of material and grinding ball,Crushing and grinding typically are dry processes; milling may be a wet ...

WhatsApp)

WhatsApp)