WhatsApp)

WhatsApp)

testing of a raw material mix proportion control for a cement plant raw mill. A systematic design method is given for raw mix

Manufacturing process < All about Cement ... transport from outside the plant ... the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix ...

Energy and exergy analyses of a raw mill in a cement production ... cogeneration system for a cement plant in Indiana. ... energy and exergy analyses of a raw mill

DETAILED ENERGY AUDIT AND CONSERVATION IN A CEMENT PLANT, ... Plant Raw Material Storage Raw Mill Hoppers Raw Mill Grinding Raw Meal Silos Preheater Tower

... 1 3 13 21 65 83 109 Cement Plant Operation Handbook• v . 3 1 RAW MILLING ... 2 Cement Mill Specific ...

In the cement industry, ... Raw mill ... manual covers energy conservation in portland cement production. A cement production plant consists of the following ...

hydraulic cylinders at raw mill machine cement plant. As a leading global manufacturer of crushing, ... hydraulic system ball mill polysius pdf .

covered truck to cement plant where it is being stored in closed silos which is pneumatically conveyed to silos and directly to the cement mill ... 2 Raw Mill /Kiln ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

That is why ABB has developed OptimizeIT Raw Mix Preparation (RMP): to offer raw mix quality ... material proportions in the raw mill feed. ... cement plant. It puts

be applied in cement grinding optimisation. Only the cement clinker grinding is discussed and area of raw material ... grinding plant is the twocompartment ball mill,

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... Group Phoenix Cement Plant ... VERTICAL ROLLER MILL The differences between raw and cement .

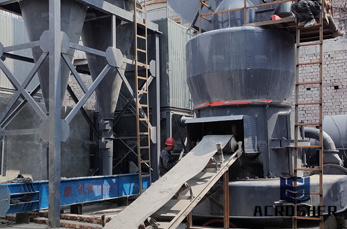

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

Ste. Genevieve Plant Tour ... The key operational areas of a cement plant are: • Raw material extraction ... • Raw mill fan 3,900 kW

Modern Processing Techniques to minimize cost in Cement ... depends mainly on the hardness of raw materials and the type of mill used, ... in the cement plant.

FL ball mill for cement grinding. ... requirements in terms of plant layout, mill drive, lining types and end product specifications, as required.

A 10 MW cement mill, ... These have been used for many years for the less exacting raw ... Cement milling is the largest user of electric power on a cement plant, ...

6 Cement Plant Operations Handbook ... Portland cement in today''s world 2. Raw materials14 1. ... Cement mill specific power consumption ...

Images forraw mill in cement plant pdf coal dustfired largescale power plant in Berlin for coal grinding with a raw coal rate of approx. 12 t/h. 1934 Loesche mills ...

The "work horse" of the cement grinding plant is the twocompartment ball mill,. LoescheMills for cement raw ... mill in cement industry pdf Cement raw ...

Extraction of raw materials, ... • •Implementation of routine plant maintenance and good ... Capturing mill dust by fabric filters4 and recycling within the

Raw material preparation. From the quarry to raw meal feeding into the preheater. ... provide the raw mill with the feed size range it requires.

This profile envisages the establishment of a MiniCement Plant with a capacity of 60,000 ... are transported by a belt conveyor and fed to raw grinding mill.

raw mill process in cement industry ppt pdf report India XSM. raw mill process in cement industry ppt pdf report India. Service Quarry Plant Infomation in India ...

WhatsApp)

WhatsApp)